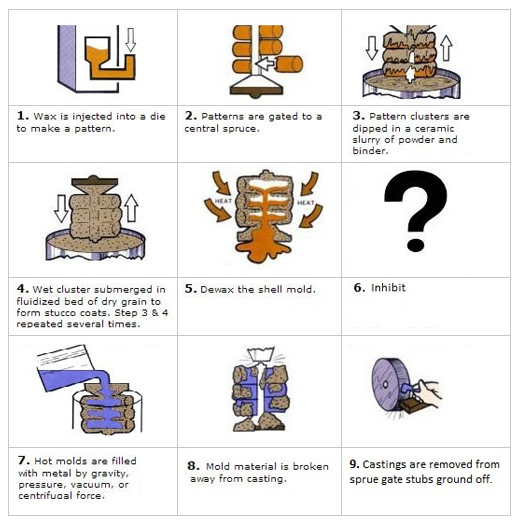

Magnesium Investment Casting Process

The term “investment” may bring dollar signs before the eyes of those who are not familiar with the process. Actually, it refers to the ceramic materials that are used to build a hollow shell into which the molten metal is poured to make the castings. The origin of the term investment comes from the solid mold process where a plaster type material is poured or “invested” into a container that holds a clustered tree of small plastic patterns that are identical to the casting being produced. After the plaster has set, the disposable patterns are burned out leaving a hollow cavity into which the metal is poured.

The same holds true for the investment or “lost wax” casting process. Wax is injected into an aluminum die to produce a pattern that is an exact replica of the part to be produced. For every casting, a wax pattern must be manufactured. The patterns are clustered around a coated sprue and repeatedly dipped into an agitated vat of ceramic and allowed to dry. After a shell thickness of approximately 3/16″ has been built; the molds are dewaxed by either flash firing at high heat (1400 F.) or autoclaving (pressure and steam). The hollow shells are then preheated to 800-2000 F. depending on the alloy to be poured and the molten metal cast immediately into the hot shell. After cooling, the ceramic is vibrated and blasted off the metal parts and discarded. The balance of the cleaning operations (cut off, grind, heat treat, straightening, blast) are straight forward and quite similar to the other casting processes.